Raw materials: Laminated with Kraft Paper, PE Film, Aluminum Foil, Pearlized film

Description

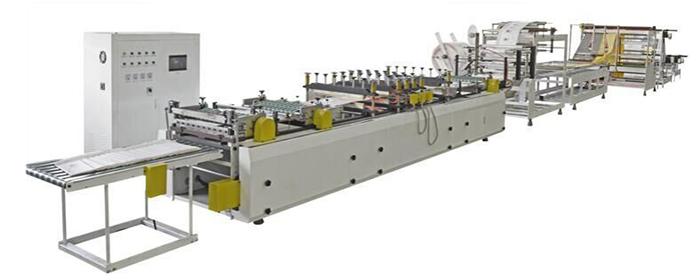

Bubble wrap bag machine consists of a bubble lamination unit, a film folding unit and an edge sealing unit. Casted frames makes the machine operate at a higher speed with less noise. This bubble film bag machine has the maximum production capacity of up to 120 bags per minute. Advanced dual servo color tracking system makes the system safer and more reliable.

Application

There are many genres of bubble envelopes with different textures, including aluminum foil laminated bubble envelop, composite film bubble envelope, co-extrusion bubble envelope, kraft paper bubble envelope and pearlized film bubble envelope. Bubble envelope is a perfect instance of bubble bag, whose impact resistant ability prevents package from being damaged of pressure, falling and collision. It is widely used in e-commerce and small package mailing business as a perfect choice for packaging jewelries, electronics and cosmetics.

Feature:

Bubble wrap bag machine can be used to produce envelops with an outer layer of Kraft paper and an inner layer of bubble film. The outer layer can also be PE film, aluminum foil and pearlized film.

| Production Capacity | 50-120 per minute |

| Minimum size of envelope | 100*100mm |

| Maximum size of envelope | 600*600mm |

| Power Supply | 380V, 50Hz/3 phases |

| Maximum Power | 25KW |

| Effective Power | 8-13KW |

| Machine size without Kraft paper composite rack | Length:10m; Width: 2.5m; Height: 2.8m |

| Machine size with Kraft paper composite rack | Length: 18m; Width 2.5m; Height: 2.8m |

| Weight | 6500kg |

Customers support

Ztech supplies bubble wrap bag machine to clients in more than 50 countries and regions around the world, including America, Canada, Russia, Japan, Australia, New Zealand, Brazil, Poland, Spain, Portugal, UK, Greece, Ukraine and Mexico.